Key Takeaways:

- For larger industrial PGM reclamation projects, utilizing a 3rd party toll refining approach is an excellent solution to help plant owners maximize the value of recyclable materials during equipment replacement or plant closures.

- Toll refining can generate a substantial return to the plant owner than paying for the disposal of valuable material.

- Going direct to processors is not always the best approach without extensive knowledge of the process and industry norms.

What type of manufacturing facility did this project involve?

This was a medium-density fiberboard (MDF) plant in the Southeastern U.S. The facility had been offline due to market conditions caused by the COVID-19 pandemic. The owner said the decision to close the facility permanently was based on a broader assessment that the older manufacturing platform was no longer competitive in the prevailing MDF market compared to the company’s other more advanced MDF manufacturing facilities.

What equipment contained the catalyzed material that could be recycled?

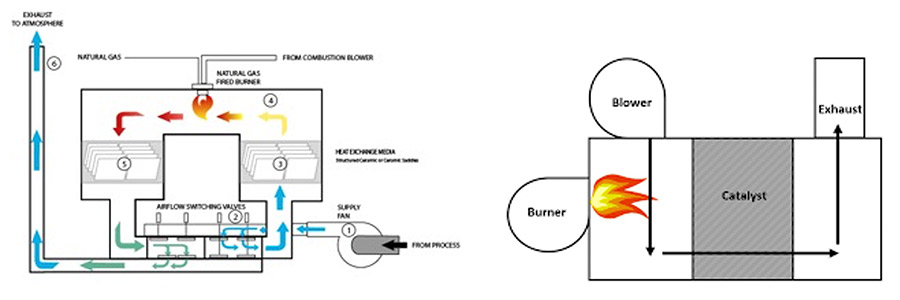

Industrial catalysts are frequently found in equipment used to treat emissions from industrial processes used in manufacturing facilities across the U.S. The common type of control equipment using PGM-bearing catalysts is Regenerative Catalytic Oxidizers (RCO). RCOs are used for controlling VOCs (Volatile Organic Compounds) across a variety of industries including:

- Pulp and paper

- Wood and board mills

- Coffee roasting

- Paint and coatings

- Specialty chemicals

- Others (see manufacturing page)

Image: Regenerative Catalyst Oxidizer illustrations

Image: Regenerative Catalyst Oxidizer illustrations

Thermal oxidizers are the primary technology used to destroy volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and to some degree, odor. These pollutants are discharged as a result of industrial processes and can be destroyed by oxidation at a high temperature. Thermal oxidizers achieve emission destruction through the process of thermal and catalytic oxidation to convert pollutants into carbon dioxide and water vapor while at the same time reusing the thermal energy to reduce operating costs.

Catalytic oxidizers are simply thermal oxidizers with an added catalyst that allow effective oxidation at a much lower temperature. In catalytic units, oxidation takes place on the surface of the catalyst.

Explain the Catalyzed Ceramic Media found in RCO equipment

The catalyzed media is most often in the form of ceramic saddles or balls coated with Platinum (Pt) or Palladium (Pd). The value of the PGM material ranges from $5-15 per pound of media, depending on the catalyst loading, media type, and spot market prices for the PGM.

Image: Catalyzed ceramic media – saddles (left) and beads (center and right)

Image: Catalyzed ceramic media – saddles (left) and beads (center and right)

Did the plant owner originally plan to recycle the catalyzed ceramic media?

No. Unfortunately, most plant owners and demolition contractors don’t realize the value of these catalyzed materials. In this case, the plant owner originally planned to pay for the dismantling and disposal of what they assumed was scrap material with little or no value. Fortunately, a specialty contractor recommended Red Fox Resources to help them evaluate their options. They decided to recycle the catalyzed material using Red Fox Resources as their toll refining partner.

Image: Catalyzed ceramic saddles before milling

Image: Catalyzed ceramic saddles before milling

What is Toll Refining?

In this situation, toll refining is defined as a situation in which the owner of the catalyzed material contracts the refining of the metal to another party (i.e., Red Fox Resources) for a fee. Still, the refined metal remains under the original ownership (i.e., plant owner) until final sale or disposition.

What were the steps for this toll refining project?

- Analyze several grab samples to characterize and value the material

- Estimate recoverable value

- Provide quotation for services including:

- Logistics and transportation

- Assays and lot management

- Processing costs (per lb treated)

- Refining costs (per troy ounce recovered)

- Deliver and process material

- Weigh, mill, blend, sample, and assay

- Provide pro forma settlement showing results and costs

- Sell metal and make payment to the plant owner

Image: Staging of ceramic media before milling at the smelter

Image: Staging of ceramic media before milling at the smelter

What were the risks for the plant owner trying to work directly with the processors?

With limited knowledge and experience with PGM recycling, there were many risks for the plant owner to proceed independently.

- Not finding the right processors to handle this particular material at reasonable costs

- Not clearly understanding the processor’s terms and minimum concentration thresholds

- Not understanding the assay process and leveraging independent testing

- Not understanding the best way to package and transport the material

- Not having an experienced broker to represent their interests throughout the process

What were the benefits for the plant owner in working with Red Fox Resources to manage the toll refining process?

- A partner with extensive experience and knowledge of appropriate processors

- A partner with extensive knowledge of appropriate terms, fees, and minimum concentrations

- A partner with extensive logistics and transportation experience

- A partner with extensive knowledge of reputable labs and the assay process

- Avoiding surprises related to meeting PGM lot minimums

- An experienced partner that is continuously monitoring the processing options and practices

- Ensuring the maximum value was returned to the plant owner (i.e., client)

- Significant revenue returned to the plant owner as opposed to disposal costs

How long did this toll refining project take?

Overall, this toll-refining process took five months to complete. This included negotiating reasonable terms on behalf of the plant owner, breaking the project into over 40 sub-lots for shipping and processing, several trips to the processing facilities for onsite reviews, and numerous independent assays to maximize sub-lot values.

What should other plant owners look for in selecting a toll refining partner to broker your project?

This is a very specialized field with limited options. Make sure your due diligence includes at least the following.

- Transparency, a clear term sheet, and an advocate at all points of the entire process

- Verifiable experience with other toll refining projects and known client references

- Knowledge of processing options, industry contacts, and industry norms

- Knowledge of assay exchange processes and splitting limit norms

- Knowledge of reputable independent labs and umpires

- Logistics experience, including packaging, transportation, and insurance

- No material moves without a fully executed term sheet

Get Started with Recycling Your Industrial Catalysts via Toll Refining

If you’re interested in recycling scrap industrial catalysts or other emission control parts, please visit our contact page or call 844-733-3695.