If you’re not already recycling, it’s time to learn the 6 ways fleets can benefit from DPF, DOC, and catalyst recycling with Red Fox.

Whether you’re a large national fleet, leasing company, or dealer group, it might be time to leverage your size and capture the income from recycling scrap emission parts. With a range of potential benefits, more and more large regional and national fleets are taking a closer look and implementing centralized recycling programs for diesel particulate filters (DPFs), diesel oxidation catalysts (DOCs,) and three-way catalysts (TWCs).

Red Fox has developed customized recycling programs for many of the Top 100 Fleets to manage the scrap from emission control parts. These fleets have seen steady revenue generation and sustainability benefits through their programs.

Below are details of the types of fleets that can leverage a customized recycling program and the primary value they are seeing.

What are the characteristics of an operation that fits this type of recycling?

- You operate 300+ medium or heavy-duty vehicles (diesel or natural gas)

- You operate your own service and maintenance facilities

- You operate your own regional parts distribution centers to aggregate parts

- You’re able to aggregate and ship 20+ emission parts (DPFs, DOCs, TWCs) at a time

- You’re interested in the added income from emissions parts recycling

- You want to discourage employees from selling your used emission parts for cash

- Your company is committed to sustainability and zero-waste programs

- You’re committed to working with a proven recycling partner who has a proven track record working with leading OEMs, fleets, dealer groups, transit agencies, utilities, and municipalities

What are the key benefits businesses are seeing through their recycling model?

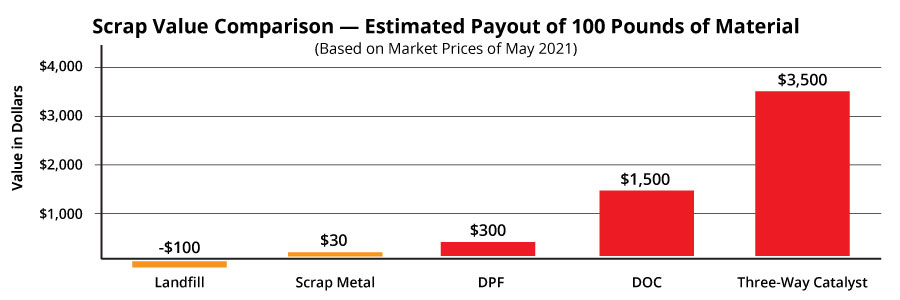

1. Revenue Generation – When done right, recycling emission control parts at scale can bring efficiencies that increase income for large national fleet operators. Although they may look like waste or scrap metal, most used emission control parts contain platinum group metals (PGM) and a value far greater than scrap metal and certainly don’t belong in a landfill. Depending on geography, scrap metal values range from 5¢/pound to 30¢/pound, compared to values of $3.00/pound to $50.00/pound for DPFs, DOCs, and TWCs. For comparison, the scrap values of 100 lbs of each type of scrap metal are below.

100 lbs of scrap metal: $30 ($0 to 30¢/pound)

100 lbs of scrap DPF PGM honeycomb material: $300 – $600 ($3 to $6/pound)

100 lbs of scrap DOC PGM honeycomb material: $1,500 – $2,000 ($15 to $20/pound)

100 lbs of scrap TWC PGM honeycomb material: $3,500 – $5,000 ($35 to $50/pound)

2. Sustainability – Many companies are committed to sustainability as a means of operating their business. Recycling is an easy and impactful way to improve the economic and environmental sustainability of our communities, economy, and supply chain. In most cases, it helps conserve natural resources, reduces environmental impact (i.e., water, air, energy, waste, pollution), and supports a localized circular economy while reducing product costs.

3. Zero Waste – Many companies commit to zero-waste or waste reduction programs like sustainability. Recycling emission control parts (DPFs, DOCs, and Three-Way Catalysts) helps businesses meet these zero-waste commitments while reducing their environmental impact and conserving natural resources.

4. Supply Chain Benefits – Manufacturers discuss developing a “sustainable supply chain.” A sustainable supply chain makes great business sense for manufacturers because producing products with reusable materials can be less costly than using all-new raw materials, reduces waste, and ensures the long-term availability of products. Recycling emission control parts is a perfect example of how businesses can promote a sustainable supply chain while reducing costs for new products and parts.

5. Good for America – The three precious metals used in emission control parts are most often Platinum (Pt), Palladium (Pd), and Rhodium (Rh). These precious metals are known as Platinum Group Metals (PGM). More than 80% of global PGM used in emission control parts is mined outside North America, primarily in South Africa and Russia. Material recycled from heavy-duty applications through Red Fox is processed and sold primarily to domestic suppliers of PGM, keeping the material in America and reducing the reliance on foreign suppliers.

6. Compliance and Hazardous Waste Risk – It’s important to remember that compliance is 100% your company’s responsibility when it comes to hazardous waste risk. This includes understanding complex local regulations and determining the potential contaminants in your waste. Different states and municipalities have varying thresholds that trigger a classification of waste as hazardous. Although the risk is low for emissions control parts, an experienced recycling company dedicated to processing these parts should be able to guide you through determining the classification of your used DPFs, DOCs, and TWCs. Red Fox Resources has conducted multiple independent laboratory tests on used emission control parts and can help companies make this determination based on our years of experience. This advice includes guiding you through the cost/benefit analysis of adequately assessing and testing your waste emission control parts.

How do I get started with Emission Control Parts Recycling?

If you want to recycle scrap emission control parts (DPFs, DOCs or Catalysts), please contact Red Fox Resources at www.redfoxresources.com or call 844-733-3695.

Other Resources

- Why Recycle Scrap Emission Control Parts?

- What is the Scrap Value of DPFs and DOCs?

- Frequently Asked Questions on DPF and DOC Recycling

- The Ultimate Guide to DPF and DOC Recycling

- Request a Price Quote for Scrap Emission Control Parts

Useful Definitions

Diesel Particulate Filter (DPF)—Diesel particulate filters, or DPFs, are exhaust after-treatment devices that trap particulate matter such as soot and ash. A DPF typically uses a substrate made of ceramic material formed into a honeycomb structure. Engine manufacturers use DPFs to trap particulate matter to meet the EPA emission standards. Most DPFs contain some combination of PGM (platinum group metals) to help facilitate emission control or regeneration.

Diesel Oxidation Catalyst (DOC)—Diesel Oxidation Catalysts, or DOCs, are exhaust after-treatment devices that break down the pollutants in the exhaust stream by using a chemical process to turn them into less harmful components from diesel-fueled vehicles and equipment. DOCs contain some combination of PGM (platinum group metals) to help facilitate the oxidation or chemical process.

Three-Way Catalyst (TWC) – Three-way catalysts are designed to simultaneously perform multiple oxidation and reduction reactions to convert air pollutants in the exhaust to harmless gases. Most TWCs contain some combination of PGM (platinum group metals) to help facilitate the oxidation process on natural gas-fueled engines.