As a precious metal recycling leader since 2013, our proven approach to PGM recycling is solving challenges for catalytic converter recyclers. With our proven track record and over 10 years of experience, Red Fox Resources has become a leader in North America for industrial precious metal recycling.

Today’s high Platinum Group Metals (PGM) prices and the recycling scrap catalytic converters business are thriving across the U.S. That said, catalytic converter recyclers face various challenges regarding smelting/refining operations. This article outlines some great solutions to help catalytic converter recyclers streamline their processes while maximizing profits.

Quick Takeaways:

- Many scrap catalytic converter recyclers also recycle DPFs (diesel particulate filters) and DOCs (diesel oxidation catalysts)

- PGM smelters/refiners don’t want the lower grade DPF/DOC material in their furnaces

- Diluting your high-grade Catalytic Converter material with lower-grade DPF/DOC material can get costly in terms of lower payouts and higher processing fees at the smelter

- Outsourcing your DPF/DOC recycling via direct purchase or toll refining is a good alternative to avoid the added costs of diluted material at the smelter/refiner

What precious metals are found in Catalytic Converters, DPFs, and DOCs?

- Catalytic Converters—Scrap catalytic converters have value because they are coated or “catalyzed” with Platinum Group Metals (PGM) such as Platinum (Pt), Palladium (Pd), and/or Rodium (Rd). Because the PGM content in catalytic converters is higher and often includes rhodium, the smelter/refiner considers this material to be of a higher grade.

- DPFs/DOCs—Scrap DPFs and DOCs have value because they are coated or “catalyzed” with a small amount of Platinum Group Metals (PGM), such as platinum (Pt) and/or palladium (Pd). Because the PGM content of DPFs/DOCs is lower, the smelter/refiner considers this material a lower grade.

Do most catalytic converters recyclers also recycle DPFs and DOCs?

Yes. As a convenience to their scrap catalytic converter suppliers, many recyclers also buy DPFs and DOCs. As a result, they need a smelter to process the high-grade catalytic converter material along with the lower-grade DPF/DOC material. However, most smelters don’t want the lower grade DPF/DOC material and, as a result, charge higher fees impacting payouts, plus higher processing fees.

Why is combining lower-grade DPF/DOC material with high-grade catalytic converter material at the smelter/refiner not a good idea?

Lower-grade material costs more to process and is less profitable because it has less PGM content. The lower-grade material derived from DPFs/DOCs also contains carbon that can cause excessive heat (i.e., overheating) in smelter furnaces. Additionally, new substrate materials in DPFs/DOCs (e.g., aluminum titanate, cordierite, and silicon carbide) are more difficult to process and unsuited for smelter furnaces.

What drives the challenges of smelting/refining catalytic converters?

It’s a matter of supply and demand. The amount of a commodity, product, or service available and the desire of buyers for it are the factors regulating its price. Today, there is more PGM material for recycling than capacity at the smelters. Therefore, smelters pick who they want to work with, and they prefer recyclers with high-grade material (i.e., catalytic converters) that are easier to process and more profitable. Conversely, smelters penalize customers with lower-grade material (i.e., material diluted with DPF/DOC content) via higher processing fees and lower payouts. Smelters want high-quality material with higher PGM content because it’s more profitable and easier to process.

What are the best options for processing DPF/DOC material by a Catalytic Converter Recycler?

To protect payout rates and minimize processing fees at the smelter/refiner, many Catalytic Converter Recyclers use one of two methods to separately process (i.e., recycle) their DPF/DOC material. This means you work with a provider specializing in DPF/DOC recycling under one of two types of agreements.

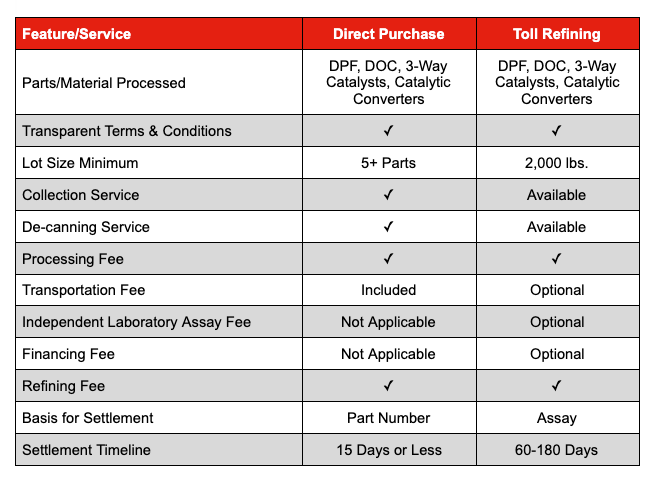

Direct Purchase Agreement

- DPF/DOC part numbers and PGM content are well known

- Payouts are part number driven, and payment is prompt (15 days or less)

- The payout process is more liquid and happens quickly

- Fees typically include Processing, Transportation, and Refining

Toll Refining Agreement

- Toll refining is defined as a situation in which the owner of PGM material contracts the refining of the metal to another party for a fee. Still, the refined material remains under the original owner until final sale or disposition.

- Used only for large bulk lots (2,000+ lbs) with little part number level PGM knowledge.

- Payouts are based on the actual assay of the crushed material, and due to a more extensive process, payment is slower (60 or 180 days).

- This purchase method is less liquid (payment in ~60 or ~180 days).

- Typical fees include processing (decanning/crushing), transportation, assaying/laboratory analysis, financing and refining.

- Companies who wish to manage their refining of scrap DPF/DOC material can make use of Red Fox Resources’ toll refining expertise, knowing that they advocate on your behalf to obtain the best terms and price at the smelter/refiner.

Toll refining customers highly regard Red Fox Resources because our approach is highly transparent and dependable.

Red Fox Resources – Direct Purchase vs. Toll Refining

What protections do I have working with Red Fox on Toll Refining?

Many customers ask about the risks or unknowns of toll refining. Based on our positive experience with toll refining, Red Fox Resources sees several protections and assurances for the customer or seller of material in a Toll Refining agreement.

- Refiners work in a competitive environment and, therefore, must offer competitive payouts.

- Material samples are often used for validation via an independent laboratory.

- If the assay is acceptable, the seller/buyers agree on a mutual buyout price.

- If the assay is not within an acceptable range, it can be sent to an independent referee and laboratory for a determination.

- Red Fox is well connected with multiple smelters/refiners who are willing to process the lower-grade DPF/DOC material.

- Red Fox proactively advocates on behalf of the PGM material owner.

- Red Fox provides a transparent and dependable process.

Red Fox Resources has an extensive background in Direct Purchase Agreements and Toll Refining Agreements for recycling scrap DPFs, DOCs, and Three-Way Catalysts used in emission control systems. Although we also recycle Catalytic Converters, our primary expertise is recycling DPFs, DOCs, and Three-Way Catalysts.

To learn more about Toll Refining with Red Fox Resources, please contact Tripp Heller at tr**********@re*************.com or 844-733-3695.