Catalytic converter recycler benefits from toll refining partners to help process DPF and DOC material, which proves cost-effective and profitable. If you’re faced with precious metal recycling challenges, Red Fox Resources has over a decade of experience to help you reduce recycling risks and improve profitability.

More and more Catalytic Converter Recyclers are starting to realize that processing material from diesel trucks is negatively affecting their core business. Alternatively, they’re utilizing a specialized third-party toll refining partner to process their diesel material and finding it a cost-effective and profitable option to process it on their own. This case study features seven (7) toll refining projects handled by Red Fox Resources® on behalf of a Catalytic Converter Recycler based in the Western United States.

Case Study Key Takeaways:

- Red Fox Resources helped assess and value the material

- Logistics and truckload shipments were all handled by Red Fox Resources

- Each toll refining project included 15-25 skids of spent diesel emission control parts

- Red Fox Resources de-cans all the parts and crushes the material

- Each project included 500-800 parts or roughly 7,000 lbs. of material after de-canning

- Payout per project averaged $55,000 or $7/lb. of de-canned diesel material

- Total customer payment for the seven (7) projects was almost $390,000 to the customer

What is toll refining?

Toll refining is defined as a situation in which the owner of the Platinum Group Metals (PGM) material contracts the refining of the metal to another party (e.g., Red Fox Resources) for a fee, but the refined metal remains under the original ownership (e.g., Catalytic Converter Recycler) until assay results are provided and the PGM material has been sold.

Why should you consider toll refining?

With today’s high prices of PGM, the recycling scrap catalytic converters business is thriving across the U.S. That said, catalytic converter recyclers also face a variety of challenges regarding their smelting/refining businesses.

What were the typical steps for a toll refining project?

- Analyze several grab samples to characterize and value the material

- Estimate recoverable value

- Provide quotation for services including:

- Logistics and transportation

- Assays and lot management

- Processing costs (per lb. treated)

- Refining costs (per troy ounce recovered)

- Deliver and process material

- Weigh, mill, blend, sample, and assay

- Provide pro forma settlement showing results and costs

- Sell metal and make payment to the plant owner

Key takeaways for recycling low-grade diesel material:

- Most scrap catalytic converter recyclers recycle DPFs (diesel particulate filters) and DOCs (diesel oxidation catalysts).

- PGM smelters/refiners don’t want the lower-grade DPF/DOC material in their furnaces.

- Diluting your high-grade Catalytic Converter material with lower-grade DPF/DOC material can be costly, as it results in lower payouts and higher processing fees at the smelter.

- Outsourcing your DPF/DOC recycling via toll refining or direct purchase is a good alternative to avoid the added costs of the diluted material at the smelter/refiner.

- If you cannot separate the different types of ceramic substrate used in DPF/DOC, you cannot maximize your payouts from your smelter/refiner.

Advantages of working with Red Fox to manage the toll refining process?

- A partner with extensive experience and knowledge of suitable smelters

- A partner with extensive knowledge of appropriate terms, fees, and minimum concentrations

- A partner with extensive logistics and transportation experience

- A partner with extensive knowledge of reputable labs and the assay process

- Avoiding surprises related to meeting PGM lot minimums

- An experienced partner who was continuously monitoring the smelting process

- Ensuring the maximum value was returned to the customer

Image: Processing scrap DPFs and DOCs for recycling (Oakland, CA)

What precious metals are found in DPFs, DOCs, and catalytic converters?

DPFs/DOCs—Scrap DPFs and DOCs have value because they are coated or “catalyzed” with a small amount of Platinum Group Metals (PGM), such as platinum (Pt) and/or palladium (Pd). Because the PGM content of DPFs/DOCs is lower, the smelter/refiner considers this material a lower grade.

Catalytic Converters—Scrap catalytic converters have value because they are coated or “catalyzed” with Platinum Group Metals (PGM) such as Platinum (Pt), Palladium (Pd), and/or Rhodium (Rd). Because the PGM content in Catalytic Converters is higher and often includes Rhodium, the smelter/refiner considers this material higher grade.

Do most catalytic converters recyclers also recycle DPFs and DOCs?

Yes. Many recyclers also buy DPFs and DOCs as a convenience to their scrap catalytic converter suppliers. As a result, they need a smelter to process the high-grade catalytic converter material along with the lower-grade DPF/DOC material. However, most smelters don’t want the lower-grade DPF/DOC material, so they charge higher processing fees and reduce payouts, penalizing customers for the lower-grade material.

Why is combining lower-grade DPF/DOC material with high-grade catalytic converter material at the smelter/refiner NOT a good idea?

Lower-grade material costs more to process and is less profitable because it has less PGM content. The lower-grade material derived from DPFs/DOCs also contains carbon that can cause excessive heat (i.e., overheating) in smelter furnaces. Additionally, new substrate materials found in DPFs/DOCs (e.g., aluminum titanate, cordierite, and silicon carbide) are more difficult to process and are not well-suited for smelter furnaces.

What drives the challenges of smelting/refining catalytic converters?

It’s a matter of supply and demand. The amount of a commodity, product, or service available and the desire of buyers for it are the factors regulating its price. Today, there is more PGM material for recycling than capacity at the smelters. Therefore, smelters pick who they want to work with, and they prefer recyclers with high-grade material (i.e., catalytic converters) that are easier to process and more profitable. Conversely, smelters penalize customers with lower-grade material (i.e., material diluted with DPF/DOC content) via higher processing fees and lower payouts. In a nutshell, smelters want high-quality material with higher PGM content because it’s more profitable and easier to process.

What are the best options for processing DPF/DOC material by a Catalytic Converter Recycler?

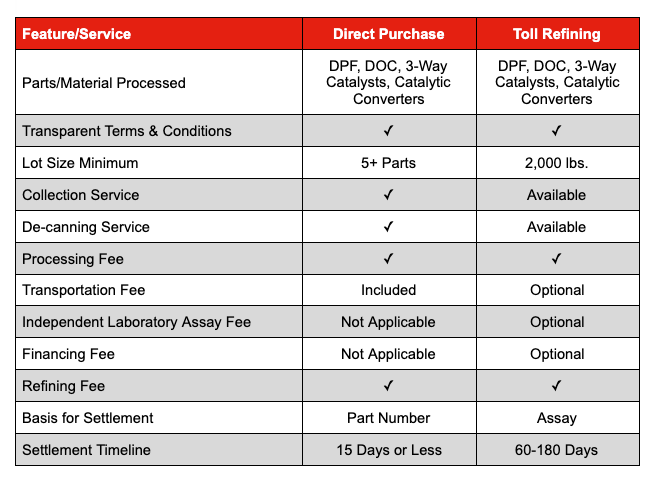

To protect payout rates and minimize processing fees at the smelter/refiner, many Catalytic Converter Recyclers use one of two methods to separately process (i.e., recycle) their DPF/DOC material. This means you work with a provider specializing in DPF/DOC recycling under one of two (2) types of agreements.

Toll Refining Agreement

- Toll refining is defined as a situation in which the owner of PGM material contracts the refining of the metal to another party for a fee. Still, the refined material remains under the original owner until final sale or disposition.

- Used only for large bulk lots (2,000+ lbs.) with little part number level PGM knowledge.

- Payouts are based on the actual assay of the crushed material, and due to a more extensive process, payment is slower (60 or 180 days).

- This purchase method is less liquid (payment in ~60 or ~180 days).

- Typical fees include processing (de-canning/crushing), transportation, assaying/laboratory analysis, financing, and refining.

- Companies who wish to manage their refining of scrap DPF/DOC material can use Red Fox Resources’ toll refining expertise, knowing that they advocate on your behalf to obtain the best terms and price at the smelter/refiner.

Direct Purchase Agreement

- DPF/DOC part numbers and PGM content are well known

- Payouts are part number driven, and payment is prompt (15 days or less)

- The payout process is more liquid and happens quickly

- Fees typically include Processing, Transportation, and Refining

Red Fox Resources is highly regarded by toll refining and direct purchase customers because our approach is highly transparent and dependable.

What protections do I have working with Red Fox on toll refining?

Many customers ask about the risks or unknowns with toll refining. Based on our positive experience with Toll Refining, Red Fox Resources feels there are several protections and assurances for the customer or seller of material in a Toll Refining agreement.

- Refiners work in a competitive environment and, therefore, must offer competitive payouts.

- Material samples are often used for validation via an independent laboratory.

- If the assay is acceptable, the seller/buyer agrees on a mutual buyout price.

- If the assay is not within an acceptable range, it can be sent to an independent referee and laboratory for a determination.

- Red Fox is well connected with multiple smelters/refiners who are willing to process the lower-grade DPF/DOC material.

- Red Fox proactively advocates on behalf of the PGM material owner.

- Red Fox provides a transparent and dependable process.

Red Fox Resources has an extensive background with toll refining and direct purchase agreements for recycling scrap DPFs, DOCs, and Three-Way Catalysts used in emission control systems. Although we also recycle Catalytic Converters, our primary expertise is in recycling DPFs, DOCs, and Three-Way Catalysts.

Getting Started with Tolling Refining

To learn more about Toll Refining with Red Fox Resources, please contact Tripp Heller at tr**********@*************es.com or 844-733-3695.

Other Resources

- Solving Refining Challenges for Catalytic Converter Recyclers

- What’s the Scrap Value of DPFs

- Industrial Catalyst Recycling Following Wood Plant Closure [Case Study]

- Frequently Asked DPF and DOC Recycling Questions