A Quick History – DPF and DOC Recycling:

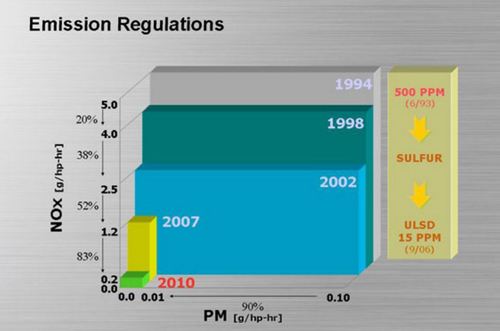

Diesel Particulate Filters (DPFs) and Diesel Oxidation Catalysts (DOCs) have been a reality for fleets and diesel service shops around the US since 2007. In 2007 the EPA ratcheted down the emission standards for particulate matter (PM) from diesel engines by 90% from the 2002 standards. As a result of the implementation of the 2007 standard, engine OEMs were then required to include DPFs in their standard engine package as DPFs are able to achieve the emission reductions needed to meet the standard. DPFs have been a standard component in diesel engines since 2007.

A Quick History – DPF and DOC Recycling:

Diesel Particulate Filters (DPFs) and Diesel Oxidation Catalysts (DOCs) have been a reality for fleets and diesel service shops around the US since 2007.  In 2007 the EPA ratcheted down the emission standards for particulate matter (PM) from diesel engines by 90% from the 2002 standards. As a result of the implementation of the 2007 standard, engine OEMs were then required to include DPFs in their standard engine package as DPFs are able to achieve the emission reductions needed to meet the standard. DPFs have been a standard component in diesel engines since 2007.

In 2007 the EPA ratcheted down the emission standards for particulate matter (PM) from diesel engines by 90% from the 2002 standards. As a result of the implementation of the 2007 standard, engine OEMs were then required to include DPFs in their standard engine package as DPFs are able to achieve the emission reductions needed to meet the standard. DPFs have been a standard component in diesel engines since 2007.

However, in California, DPFs have been in operation long before the implementation of the EPA 2007 standards. In 2000, the California Air Resources Board adopted the Diesel Risk Reduction Plan after diesel particulate matter was determined to be a Toxic Air Contaminant by the state in 1998. The Diesel Risk Reduction plan set in motion numerous regulations aimed to reduce diesel particulate matter emissions from specific segments of the diesel engine population. Transit, solid waste collection (refuse), public fleets, vehicles serving ports and private fleets were all subject to separate CARB regulations aimed to reduce their PM emissions. Applying a CARB approved retrofit DPF to pre 2007 model year engine became a key compliance component for fleets needing to meet various CARB regulations.

A Developing Waste Stream Born from Regulation:

As DPFs and DOCs have now been on the road for more than 10 years, fleets and shops can attest to the fact that DPFs fail and need to be replaced (a story for another blog). Also, many DPFs are installed on vehicles that have reached the end of their useful life (primarily the retrofits in California, as diesel trucks tend to run for 15 -20 years). Like many truck and engine components, DPFs and DOCs have residual value greater than that of their scrap metal value so it makes sense to recycle these systems and not to simply include them in the scrap metal lot that typically gets sent to the crusher at the end of a truck’s life. Red Fox has identified solutions to dealing with this developing waste stream and offers fleets a solution that makes good business sense.

3 Key Reasons DPF and DOC Recycling is Good for Business:

3 Key Reasons DPF and DOC Recycling is Good for Business:

1. There is monetary value in the failed or spent DPF core:

To put it simply, most DPFs and DOCs are coated or “catalyzed” with Platinum Group Metals (PGM) in order for the chemistry in the exhaust stream to mix correctly and ensure that engines meet the actual CARB and EPA emission reduction requirements. PGM in DPFs and DOCs can be recovered and recycled by a specialized diesel emission component recycler like Red Fox. Red Fox will purchase failed DPFs/DOCs to recover the PGM material. A failed or spent DPF or DOC can typically be worth $25 – $700. The alternative to recycling the material is scrapping it and earning roughly $0.50 -$3 or tossing it in the dumpster and paying to have it removed.

No good business would choose to continually pay their waste company to haul off recoverable assets worth $25 – $700.

2. Recycling DPFs and DOCs keeps prices down for new parts:

Manufacturers talk a lot about developing a “sustainable supply chain.” A sustainable supply chain makes great business sense for manufacturers because obviously making products using reusable materials can be cheaper than using all new components, it reduces waste and ensures long-term availability of products. Recycling DPFs and DOCs is a perfect example of how businesses can promote a sustainable supply chain while keeping costs for new products down.

As engine manufacturers continue to make engines with catalyzed DPFs they’ll continue to pressure their upstream DPF suppliers for lower prices. The DPF manufacturers are also looking upstream to the raw materials suppliers of PGM for lower prices, but the PGM prices are tied to the market commodity price. Assuming continued demand for the material is consistent, the only other lever to pull in order to keep the price down is to increase the supply – and providing the catalyst suppliers with recovered PGM that would have otherwise be landfilled or is sitting on shop floors around the country is a great way promote sustainability and keep costs for new parts down.

When a fleet or shop recycles a DPF they are promoting sustainability (reducing the need to mine new material) and bolstering the supply of a scarce product, thus keeping the price for the new DPFs and DOCs down.

3. Recycling DPFs is good for American business

Over 90% of global platinum is mined outside of North America, primarily in South Africa and Russia. Material that is recycled from heavy duty applications through Red Fox is processed and sold exclusively to domestic suppliers of PGM keeping the material in country reducing the reliance on foreign suppliers.

Frequently Asked Questions | How It Works | Get A Quote

For more information on our DPF recycling buy back program and our process, you can explore our website and get in touch with us here.